I've taken several stabs at dagger making recently. I have a question regarding grinding in the bevels.

How should the grind angle change over the length of the blade? It must change at some point, or else you'd end up with a thin-skinny-weak tip. Is it just a gradual change along the entire length of the blade, or do you keep the angle constant and then sweep it steeper near the tip?

Lately I've been leaving the profile of the tip a little wide through forging, heat cycling, and rough grinding. I then grind in the same angle all the way to the tip. After I get it hardened, tempered, and polished (still with the wide tip) I take in the profile of the last inch of the blade to a point (with a slow grinder) and grind/sharpen/blend the tip. This gives me the same plane all the way to about the last inch of the blade and then a reinforced tip.

Am I doing it correctly? What method do the experts use?

Any advice is appreciated.

Steve

With any thing that has any sort of distal taper that is out of sequence with the profife the grind will have to warp out of plane. I have noticed the same thing needs to happen on large bowies or fighters.

With daggers there are several ways to approach this depending on the desired result. Many daggers are thick and robust thinning toward the point but still remaining substantial in thickness,some of these might had a reinforced point as well, these are trusting daggers. Some daggers on the other hand are thinner with less distal taper maintaining a cutting geometry all the way to the point these are intended for slashing cuts as well as thrusting.

In swords we see these changes become even more drastic and the differences between cutting and thrusting geometries in some cases being extremely pronounced. This added to the fact that swords in general do not have linear distal tapers can mike the grinds tricky to say the least. On Original swords the thickness tends to drop in stages this is necessary both for the sword to handle correctly and to flex evenly. It can be quite a trick to get the bevels to appear flat and maintain an even edge thickness.

MP

Matthew--Thank you for the information. Yes, I'm starting pretty thick (about 3/8) and then tapering with the profile taper...but trying to end with a sturdy thrusting point. I can't imagine making a dagger that was not built for thrusting.

Is anyone familiar with a "standard" for the Mastersmith dagger? It would interesting to know if there are any basic dimensions, thicknesses, or other guidelines (unwritten, probably) that people keep in mind when thinking about how the thickness of the dagger varies along the length.

The angle of the bevel must change any time the edge makes a curve, if you want to maintain the edge thickness. With double edged blades, there are two different distal tapers involved at some point along the length of the blade. There is the profile taper and the blade thickness taper.

When I make a dagger, I have forged the profile taper in, but not so much the thickness taper. I find it easier to grind the thickness taper. I start with bevels forged in and a little thickness taper, but not as much as I want in the finished grind. Thickness along the center ridge is fairly uniform.

Looking at one face of the blade there are two edges. Grinding the first edge will grind past the center line (on the face) where the thickness taper begins out to the point. Grinding the other edge restores the center line and presto, you have just ground a distal taper in thickness. I hope that makes sense.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Steve, see if this as-forged picture helps

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

|quoted:

... I can't imagine making a dagger that was not built for thrusting...

Indeed. The very definition of a dagger that distinguishes it is its specialization in thrusting attacks. There are other knives from other cultures, some double edged, some single that were used for thrusting, while some for slashing, but they would have their own names and designations within the language, or culture, of their origin. English speaking peoples have a penchant for giving our labels to artifacts of other cultures. These blades have what I describe, when teaching how to make them, as a "helical grind" starting as a flattened diamond near the ricasso and steepening to a square at the tip for strength and rigidity. This may give knifemakers concern about the edge keenness, but this why knifemakers will always struggle with daggers until they abandon the concept of a double edged knife and embrace making the thrusting weapon known as the dagger. I also teach the two different tapers- cross sectional and profile, and most knifemakers struggle with the profile taper, making the job much tougher and compromising the streamlined thrusting efficacy.

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.

|quoted:

These blades have what I describe, when teaching how to make them, as a "helical grind" starting as a flattened diamond near the ricasso and steepening to a square at the tip for strength and rigidity.

That's what I'm starting to realize--each bevel of the dagger isn't really a plane, but a surface that is gently twisting toward a square tip. So I'll need to roll the knife when grinding along the entire length of each flat, more or less, making it have much less distal taper than I've been allowing for so far.

|quoted:

That does help. Nice forge work--very clean.

|quoted:

The angle of the bevel must change any time the edge makes a curve, if you want to maintain the edge thickness. With double edged blades, there are two different distal tapers involved at some point along the length of the blade. There is the profile taper and the blade thickness taper.

When I make a dagger, I have forged the profile taper in, but not so much the thickness taper. I find it easier to grind the thickness taper. I start with bevels forged in and a little thickness taper, but not as much as I want in the finished grind. Thickness along the center ridge is fairly uniform.

Looking at one face of the blade there are two edges. Grinding the first edge will grind past the center line (on the face) where the thickness taper begins out to the point. Grinding the other edge restores the center line and presto, you have just ground a distal taper in thickness. I hope that makes sense.

That makes sense. I've been doing as you describe, more or less, but since my daggers have an acute triangular profile I end up getting way too thin.

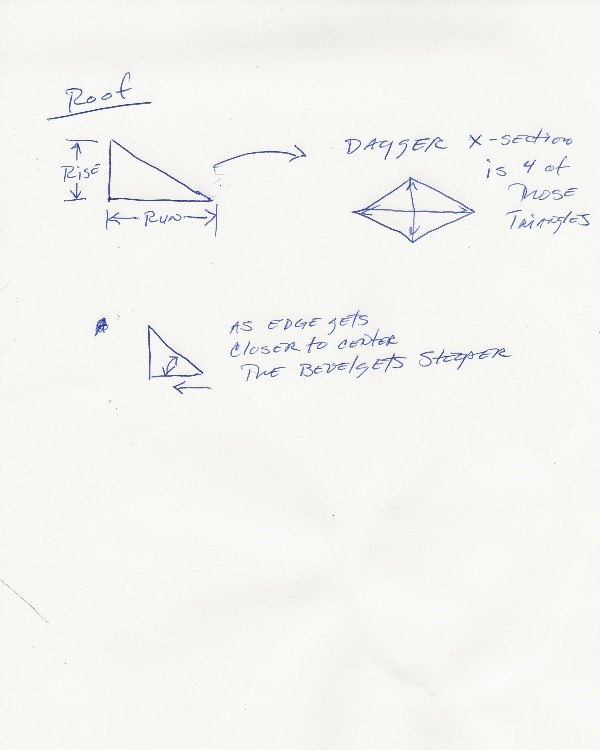

It sounds like you have more thickness taper than you need. The profile taper is very sharp, so it changes much faster than the thickness taper should. The only analogy I can think of is in home building and roof construction. The pitch of a roof is measured in rise vs. run. Rise being the vertical distance from the top of the bearing wall to the ridge, and the run being the horizontal distance from the ridge to the top of the bearing wall.

So as the "run" of the dagger edge to center line gets shorter (profile taper) the bevel angle gets much steeper, with the "rise" (thickness taper) not diminishing as fast as the run changes. This produces the helical grind that Kevin is talking about.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€