Im making one, but the reason was to push myself and my techniques. That being said, I really cant see an advantage other than proving you can? What are the advantages of a take down knife?

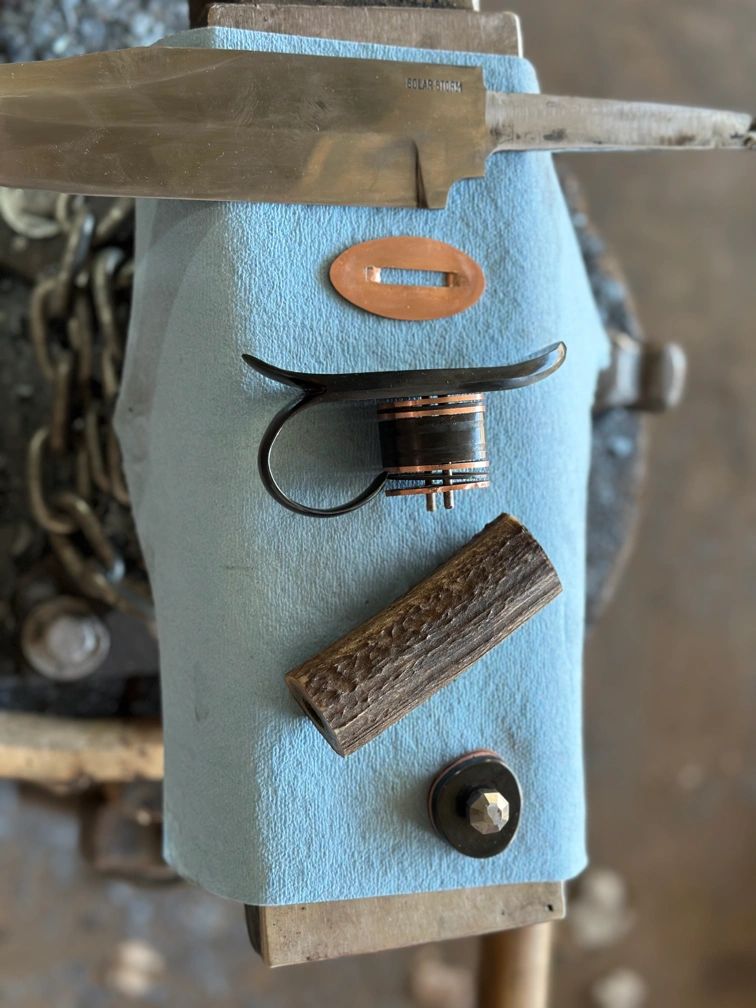

Here is my current work in progress. 8" ring guard bowie.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Outside of the bling factor, there may be some maintenance considerations. It may be a good idea with something like ivory or other sensitive materials that may benefit form an inspection and cleaning of internal components. All of this aside, I encourage, and even strongly recommend that any maker going for Journeyman or above in their craftsmanship level do at least one takedown knife. It is the best self-training you will ever get in proper fit and finish. The standard technique that we all start with of gluing it all together and then finishing will only take you so far in honing your craftsmanship. The tolerances and attention to detail will get you over that hump in your skills and take all of your knives, even the glued up ones, to the next level.

Kevin R. Cashen I agree on the self training. This has been painstaking slow and I have made the guard and spacer twice… still not entirely happy with the ring, but time is also pressing. I still have 1 ½ years before I can attempt my JS. So a bit of time to get better yet.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

9 out of 10 bladesmiths will tell you that the process of gluing up the handle to the blade is one of the most stressful operations, if not the most stressful. The take-down method of construction eliminates the glue-up. If you are using a frame handle with take-down construction, the most stressful operation becomes doming the pins! 🤣

If you are using a solid handle, the most stressful operation becomes bedding the tang (unless you don't use epoxy to bed the tang, which I don't use)

Other than that, a take-down handle is almost impossible to put together crooked, if you have taken the time to make sure all of your mating surfaces are flat and parallel.

I almost never grind the handle on the blade. Almost all of my handle shaping is done off the blade, regardless of handle design. The only exception is on a full tang handle knife, and I rarely make those any more. The last one I made was a pattern welded blade and the handle scales were shaped on the knife with temporary pins so I could etch the whole blade and handle.

The take-down method, once you develop a process, is a much more prcise method. It makes you fit everything perfectly and allows more opportunity for artistic embellishment. For me, that's the part I really like.

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.”

Thanks everyone, I am definitely learning... I have made some of the handle pieces 3 times now, and am dreaming of a mini mill... (someday)

It is a bit of a PIA but I am liking the precision of the fit, especially how I contoured the copper spacers to match the ridges in the antler.

I have done way more than the client asked/paid for, but he was a military firefighter that was injured in a propane fire, and just feel I need to deliver something special.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

It is a bit of a PIA but I am liking the precision of the fit, especially how I contoured the copper spacers to match the ridges in the antler.

One suggestion I have: It looks like you are using 3/32" pins. I use 1/16" pins. I buy .062" music wire from Ace Hardware. It is HC steel in spring temper. two 36" pieces are a couple of bucks. I find the smaller diameter pins just work better. Less chance of slop and movement

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.”

Another suggestion: Get a piece of threaded rod (I use 8-32) and some nuts & washers. I grind one end down a bit so it fits through the spacer package. You have to be careful to keep the ground faces parallel. Either get some soft washers or make some leather ones to keep from scrathing the faces and end cap. Now you can hold the handle assembly together without using that bar clamp.

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.”

The ground down end

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.”

Handle held by threaded rod

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.”

Thanks, the pins are some 1/8 steel, but I will check out the 1/16. probably a better idea.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Great idea with the threaded rod! Simple but brilliant

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Some more progress.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

Michael Samdahl Yup, the vids you are doing on youtube are a good lesson for your customers though. the more they understand the more they appreciate the work.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke