|quoted:

All of my knives are differentially heat treated to some extent. Are they performance test knives with dead soft spines? No. I dont want one to bend when under heavy stress, I want it to flex. It's still differentially heat treated. The cutting edge is the hardest gradually softening on the way up and back, but not dead soft till it reaches the tang/ricasso juntion.

I've seen a few bend and take set during the 2X4 chop in competitions. I believe there is a misconception that the best knife blades are drawn down dead soft on the spine. This belief stems from the way we are taught to heat treat a performance test blade. Drawing the spine is recommended for the test blades. Sure. Other than that, I dont draw the spine dead soft and I dont draw the soft area down very low on the blade. A dead soft blade feels dead in the hand and it dont perform as well. Especially when it will bend and take a 10 degree set if you slap it across a 2x4 on it's side.

I've seen one blade break in competition due to being too hard at the tang ricasso junction. Either way, something was done wrong in the heat treat.

|quoted:

I heat treat mine the same way Lin does. I do not want a dead soft spine. I want flexibilty in my knives, not bend and take a set...

I cannot tell you how happy it makes me to see such clarity of thought and insight on this topic from two of our finest Mastersmiths such as Lin and Brion. This is not the place for one of my favorite dissertations on elastic vs. plasticity in blades but I would be happy to have a detailed discussion in the heat treating forum. There was a time that the widespread misunderstanding of the basic physics behind the subject would have skewed most present, including many Mastersmiths to the dead soft spine train of thought. To be honest I was expecting it because I was not aware of how well the ABS has done in offering sound information until I read these posts, and it is a very pleasant and welcome surprise.

Every knife I ever used in competition was at least 58 HRC everywhere except the very end of the tang, but the heat treat was the very best I could do. Not only were they subjected to extreme hard use in the competition/demonstration, but they were subjected to hours of pure torturous use long before arriving at the event. I was asked on several occasions at the last moment to participate, meaning I would have to make a knife without my heat treating equipment and standards. Not only did I firmly decline, I was surprised that somebody would ask that a knife made in such a haphazard manner be used in competition. Not only do I totally concur with Brion and Lin, but I also would have refused to participate in competitions/demonstrations if I were forced to use the differential hardened method. Not that that method would be inferior in the competition venue, unless it should bend in use whereas it would obviously be inferior, but I always competed with the best examples of my work which would not have included a dead soft spine.

The idea behind the cutting demonstrations were to focus our attention, and get us all thinking, more heavily on blade performance and raising the bar on optimum heat treatment and edge geometry. Things like enlarged grain and other “oops†in heat treating can be an opportunity to learn, or they can set us back if we start lowering the bar to accommodate them rather than overcoming them. Rather than lowering that bar, I would suggest a better way to deal with the issue would be to be certain the participant blades have been tested. Perhaps a private prequalifying trial of very heavy chopping before the actual event would be a good way to eliminate many of these problems.

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.

Thank you Kevin. I believe we all should put this amount of thought and testing into our knives. Pretty much all of my competition knives are full quenched, tempered, then the tang drawn soft and the spine lightly drawn back. This drawing back with a torch is done at least twice in a water bath. I said pretty much all of them. Here is a big spearpoint bowie in 1095 with a hamon. So you know the spine is definitely not as hard as the edge.However this knife has a spine of almost 3/8" thick. Not very flexible.

With this knife, while it chops well, it does not do as well on finesse cuts, mainly because of the weight. I would also change the handle design slightly to give more of a finger hook at the end. The lanyard attaches to the tang which goes all the way through the handle. So there is a secure attachment point. There are also two pins.

This knife is a typical bowie style. The top clip is sharpened. The blade is almost ten inches, and is 1 3/4" wide. The steel is the new steel that I am testing. So far it has held up just fine and is doing very well. The tang and a part of the spine are drawn back as mentioned and the blade was full quenched. The handle I like on this one. It feels great and does not slip. This blade is a little bit light as it does not do as well on the 2X4, but it does well on the finesse cuts, such as straws and empty coke cans. Could be operator error too. You should also notice the lanyard attachment point on the guard. Some one named Lin used this and I asked if I could try it. He very graciously agreed. Thank you Lin.

Both of these knives have been tested at my shop extensively and out in my yard. Both have been used in competitions after testing. They work well but could use some tweaking. My next design will incorporate those tweaks. Always learning.

One thing, you should always test your knives before using them in a competition and test them extensively. That way you know what they and you are capable of and if there are any problems, like a heat treating problem.

Gary as far as the testing of knives before a competition. I am not sure how we could go with that. Maybe as Kevin states a pre-cutting test, or a description of your heat treatment for the knife. I am not sure just an inspection would reveal anything out of the ordinary. I will think on it.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Thanks Kevin.

Brion, it's good to see the comparison of your two knives and how your thinking reflects the stratigy change. It's similar to mine in that I'm backing away, just a little, from the heavy bladed cleaver design(never was too keen on it's looks)in favor of a bowie design. While it might not "win" as many chopping competitions, it averages out to be a more servicable knife, in my opinion.

I'm noticing that in the photos, most of the knives are hidden tang construction. This goes against the rumor that "a full tang knife is stronger". In fact, again in my opinion, the well made hidden tang knife is just as strong, if not stronger. It's not the general construction, it's the detail that goes into the construction. The good fit on the joints and the careful thought about the handle material, pins, tang taper, hard/softness, etc. Good fit and mechanical integrity is the primary strength of your knife's handle.

I'll give you an example. Let's say you have a heavy I-beam..... and butt weld a 3/8 X 12 inches all-thread to the side of it, 90 degrees. Now slide a 1 inch pipe 11 inches long over the all thread and put a washer and nut on it and snug it. As long as the all-thread is centered up and the ends are square and the slack is out, and the weld is good, you can turn that I-beam over and move it around with your new handle. With your "handle" construction and good fit, you have changed the direction of the tangs duty. It's all tensil now. Just something to think about.

I dare say Brion beefed up the tang inside the horse stall mat to compensate for the relatively soft handle material. He and I have discussed that is why I say that.

I dont mean to hog this conversation.

I'm kind of surprised, not more have commented on this thread. I believe there is much more about competition/camp knives that could be discussed. Handle design, for instance. Brion touched on it about the horse stall mat. That material has obvious grip qualities that would help.

But, what about shaping a wood handle that would resist slipping or turning in your hand during a repetitive cut, like chopping. Also, is it possible that you WANT some slippage? It may be counter intuitive, but I will stick my neck out (again <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />) and suggest that there needs to be some latitude for the hand to make small shifts on the handle that would help perform some cuts. The contouring should work with the material of the handle assiting it's tackiness or lack of tackiness. A mix of two materials might be worth a try. I've been thinking about using a wood handle with inlays of horse stall mat.

|quoted:

I dont mean to hog this conversation.

I'm kind of surprised, not more have commented on this thread. I believe there is much more about competition/camp knives that could be discussed. Handle design, for instance. Brion touched on it about the horse stall mat. That material has obvious grip qualities that would help.

But, what about shaping a wood handle that would resist slipping or turning in your hand during a repetitive cut, like chopping. Also, is it possible that you WANT some slippage? It may be counter intuitive, but I will stick my neck out (again <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />) and suggest that there needs to be some latitude for the hand to make small shifts on the handle that would help perform some cuts. The contouring should work with the material of the handle assiting it's tackiness or lack of tackiness. A mix of two materials might be worth a try. I've been thinking about using a wood handle with inlays of horse stall mat.

Lin, I'm glad you brought up this Point. It was always my habit to compete with a knife that was not too specialized. I wanted to compete with the same kind of knife that I used around the house and in camp(not that different for me). I always apreciated that the eveny coordinators worked hard to come up with a number of cutting events that would test all aspects of knife and cutter. Not only did I prefer a general use blade shape, but I also preferred to use a fully finished knife that was exactly like the ones I sell. That means that I used a variety of handle materials, making the design of the handle tantamount to the material. I once even competed with an ivory handled Damascus knife. Tho point of all this is that I believe a properly designed handle is as important as a carefully crafted blade. The handle is the controls of the knife, and if you can't controll your knife, it doesn't matter what your blade is.

Having said that , I competed with many different steels, and I can never blame a loss on any of them. My favorite though would probably be W-2.

Although it's been awhile since I've competed I don't believe my approach would change much. I believe many steels will perform well as long as they are heat treated to bring out the best they have to offer, that said my steel of choice has always been 52100. It's the steel I've spent the most time with and done the most experimenting with and I feel that it's possible to get this type of steel to conform to lots of different tasks. Again knowing the material well and how it reacts to different heat treatments will allow you make a knife that will cut like crazy and still be tough enough to chop through a 2 x 4 without failure. The competition knife for me is quite specialized in that I'm building it with all the challenges in mind that might show up in the competition. It's close to what my camp knife design is like although the comp. knife would be a bit heavier. I like my comp. knife to have some heft to it so I'd leave the back around .200+ with a nice distal taper and a convex edge which is more stout at the heel and thinner at the tip. I like a bit of "hook" or birds head at the back of the handle so that the tendency for the knife to slip out of my grip is diminished. If the handle is designed correctly for my hand then the material does not seem to be as important although I do like the horse mat material for it's grippyness. Hardness would be 61-62hrc. That's half of the equation, the other maybe more important part is the guy wielding the blade. Focus, practice, confidence and experience all contribute greatly to the guys who win.

BK

I too, like to have a point on my knife. A very sharp point that will puncture a barely filled balloon with water by thrusting it. I believe that the best steel is 52100, because it is supposed to be able to have the grain reduced to the smallest size. This is important in edge holding properties. The other important points have already been discussed about the shape of the handle and its ability to be used under adverse conditions with comfort. The very best steel for you to use in cutting competitions is the one that you have developed a heat treat for and have tested.

The ultimate edge is one that will be thin enough to slice everything you put it to and thick enough not to wrinkle. Notice I didn't say chip. To me, if it chips, it is too hard and needs a slightly higher tempering temperature. That is me as I don't like chips in my edge.

To get the ultimate edge, I start a little thin. I cut, chop, slice, dice, some of the harder materials than normally found in the cutting contests. My edge will usually get some small wrinkles in it. I sharpen it again and in doing so, makes the edge a little bit thicker. I go through the cutting tests again. This is repeated till it no longer will wrinkle. At that point, I will sharpen it ONE more time before competition. I make sure that the edge of the sharpening bevel is rounded into the blade and after a new 400 grit belt, hard Arkansas stone, and the buffer to put the ultimate sharp edge on the blade, I will strope it on my razor strap 20 times on each side every day for two weeks. It is then as sharp as I can get it.

The sheath for this blade will need to be a bit wider than the blade. I slide the blade into the sheath, makeing sure the edge doesn't touch anything. I do not let anyone touch it till after the cutting contest. After the contest, sure, show it to every one and let them touch the blade and cut something else. Cutting with a very sharp knife is slightly different that getting it close to very sharp. I have tried a few times with an impromtu cutting and it isn't the same edge. When I say impromtu, I am not talking about a blade that hasn't been tested, just not sharpened as well for the contest to a super sharp condition.

On cutting the rope that Mike Williams was talking about by Bill Moran and his six inch blade. When I won the 5" hunting knife cutting contest at around that time, I cut the rope for Mike as he was explaining knives to some visitor, with the same 5" knife. The edge geometry has to be correct to pass through the rope. Speed is also critical as well as angle.

All these things require a lot of cutting at home and in the field. ALWAYS test your blades as much as you can before competition. It saves a lot of time.

Something that hasn't been addressed much is blade geometry. Something that I have done to previous blades is after flat grinding the bevels, back grinding the spine slightly to reduce the drag. I realize that this reduces the weight of the blade but that should be minimal and the reduced surface & drag of the blade should more than compensate for it.

My next tweek for a competition blade that I am planning is to give it a double taper with a distal taper from the "sweet spot" to the tip and a reverse taper to the back of the blade. Since I haven't tested this geometry yet, it remains to be seen if an extra thick sweet spot is advantageous but the idea seems worth trying.

Gary

Well I finally got logged on and am at the tail end of this BUT I still want to put my two cents in. First of all I applaud one and all for a great topic and discussion.

I have been cutting since the first competition way back when and it has come a long way. What originally endeared the ABS to me was that the knives had to perform as well as look good, be of sound design and construction. I liked that the maker had to be the one to put their own work on the line and be compared to the other contestants. I love it when the talk has to stop and it is time to actually, physically, demonstrate. I liked that the events were kept secret until show time; that way we had to make all round knives and not knives specifically for predetermined events. It is more realistic and practical in my mind.

I think we all know that design, heat treat, geometry and good craftsmanship are the ingredients for an exemplary knife. I agree the handle is very important but I also have to admit/ agree that the "rubber" handles are better if not very attractive. When I am not competing it makes little difference to me if I have to re grip while chopping or how long it takes, so other than rubber is fine and more attractive.

I like most of the steels we use but prefer a little more carbon in a competition knife. (75 + points) Sometimes I think we tend to take what we do for granted. What we do takes some skill and knowledge. I have heard of several knives breaking in competition and that is dangerous as well as negligent. I would not go to compete without testing my knife which would hopefully preclude any mishaps at the competition.

Briefly: I tend to prefer a full tang these day but have used many a narrow tang as well. I like a low point and like the cutting edge to be slightly curved and stay "flat" as long as possible before going up to meet the point. This enables me to cut stuff flat on the table. IE tennis balls, ping pong balls, dowels, bottles, cans etc. I like as as heavy a knife as I can handle well and move quickly. No distal taper here, I am looking for weight.

The AKA and I are having a Shop Visit at my home Saturday December 1, 2012. The topic and demonstration is: "The design, construction and use of a practical competition knife" The plan is to make a simple competition knife and put it through it's paces during the visit which will culminate with a cutting competition/ demo orchestrated by Jason Burton. Lunch will be served.

Best to all,

Jim

Jim, will this also be the business meeting of the AKA? I will be there and let me know if you need anything.

See you there.

I am getting in a little late, but have enjoyed reading the discussion. Not really sure what I can add to what's been said, other than I did beat Jim Crowell in a competition once. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' /> on a more serious note, making competition knives forced me to really test edge geometry. To borrow a phrase from Kevin, geometry cuts. After finding what I thought was the ideal edge geometry for my steel and my heat treat, I had to learn to duplicate this same geometry over and over with accuracy. Personally, I was surprised at how thin I could go if everything else was "right". It also made me a better knife maker.

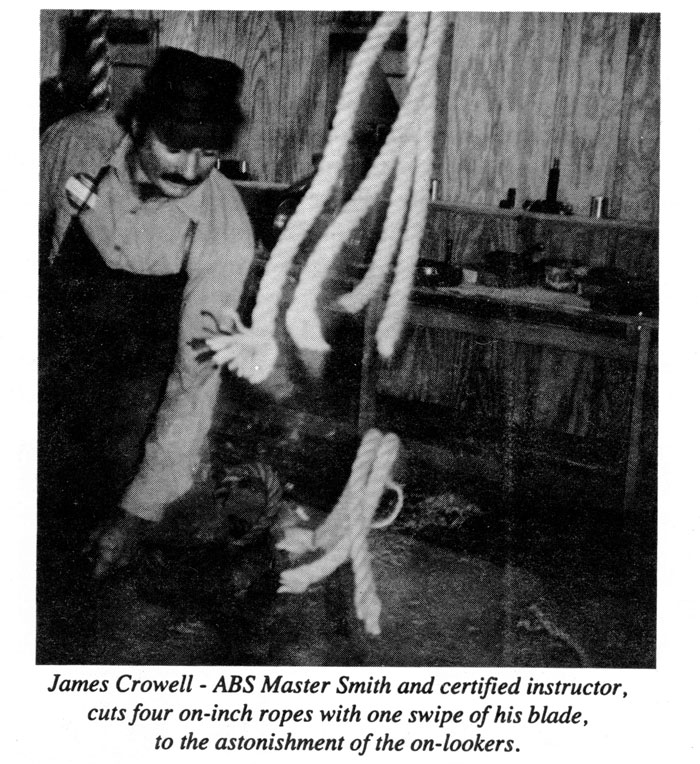

I was going through some old ABS records yesterday and found a photo of Master Smith Jim Crowell cutting 4 ropes in one swing in an ABS publication entitled "History, Vol.III- 1993". I thought that our members would like to see it.

Very impressive, Jim!

Dan Cassidy

Journeyman Smith

Send an email to Dan

|quoted:

I am getting in a little late, but have enjoyed reading the discussion. Not really sure what I can add to what's been said, other than I did beat Jim Crowell in a competition once. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' /> on a more serious note, making competition knives forced me to really test edge geometry. To borrow a phrase from Kevin, geometry cuts. After finding what I thought was the ideal edge geometry for my steel and my heat treat, I had to learn to duplicate this same geometry over and over with accuracy. Personally, I was surprised at how thin I could go if everything else was "right". It also made me a better knife maker.

I was sick that day ; )

|quoted:

Jim, will this also be the business meeting of the AKA? I will be there and let me know if you need anything.

See you there.

We usually have the business meeting at this event but I have not been officially informed.

I think we have it covered. Of course bring anything you have that would be of interest like steel or handle material etc.

|quoted:

I was sick that day ; )

You seemed ok for supper at Outback Steak House before. Maybe you got a little puny afterwards. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' /> BTW, I still have the knife we took first and second with at the first Haywood hammer-in. How's my teddy bear doing? I admit, you beat me fair and square that time.