Well historically presentation weapons were more embellished pieces of dress wear that happens to be a knife, the exception being the Germanic slave master giving a freed slave a sword. so am I to make a blade that is meant to warn for show or a blade meant to be used?

I’m concerned that there is a concept that the two are exclusive. If a knife can’t be used, regardless of how embellished, it is not a knife. I have made some pretty lavish pieces in my career but every one of them was capable of performing their intended task to the utmost that my abilities would allow, or my name would never have gone on them. I have even had clients suggest that I didn’t have to have the utmost heat treatment or sharpened edge since it was just going to be a “wall hanger†and I suggested that they needed to find another smith.

As a judge, I would say that if you brought me the plainest knives in the room but they felt good, were cleanly constructed and left no question that they would perform well, you would win the prize. I have failed my share of over-embellished knife shaped objects. I am looking for a Journeyman bladesmith, not a journeyman metal sculptor. All that being said, once you have a quality tool, and you actually have the skill set to do it correctly, making it beautiful with embellishments is just icing on the cake, but that shouldn’t ever detract from its function.

For example, I am holding a beautifully balanced knife with flawless fit and design, the edge seems sharp enough to split an atom. The maker decided to gild the lily with an actual proper choji hamon, but for about 3/8†the habuchi drops low enough to go off the edge. I feel this is a fail. There is a section of the edge that can clearly be seen as not heat treated at all. Neither the other qualities, or the beauty of the hamon shape can make up for the fact that the edge is compromised on what is first and foremost a cutting tool. The next guys knives are basic hardwood, nickel silver, and 400X satin finished steel, but they are all solid using knives, he wins the prize because he worked within his abilities to make the best work he could. Hamons, or inlay, or engraving are not his forte, so he wisely stayed within his skill set.

"One test is worth 1000 'expert' opinions" Riehle Testing Machines Co.

Kevin, There are numerous photos of successful JS knife sets on the ABS website. You can see them by clicking the link toward the bottom of this page: http://www.americanbladesmith.com/index.php?section=pages&id=172

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Wait there is a prize involved...cool, I did not consider that, as just having my blades critiqued by a panel of masters is prize enough for me as frankly, I can only ever see the flaws in my work. Also the only embellishment I have learned so far is file work and If i understand the theory right this embellishment can add a functional beauty to the blade more tip heavy allowing for greater potential chopping power. plus i kinda like the blade to speak for its self rather adding extravagant fittings.

Also really most of the presentation weapons of the passed i have looked at are not from the modern times. also... I have never actually scrolled down that far on the JS test page cause I have always just scrolled down far enough for the judging parameters. and honestly, I will not even bring apply for the test till I know the knife I made will pass the thing.

![]() which means i get to have fun practicing making the blade a few times to make sure it will pass the bending test, a good thing since I need the practice cloning blades

which means i get to have fun practicing making the blade a few times to make sure it will pass the bending test, a good thing since I need the practice cloning blades![]()

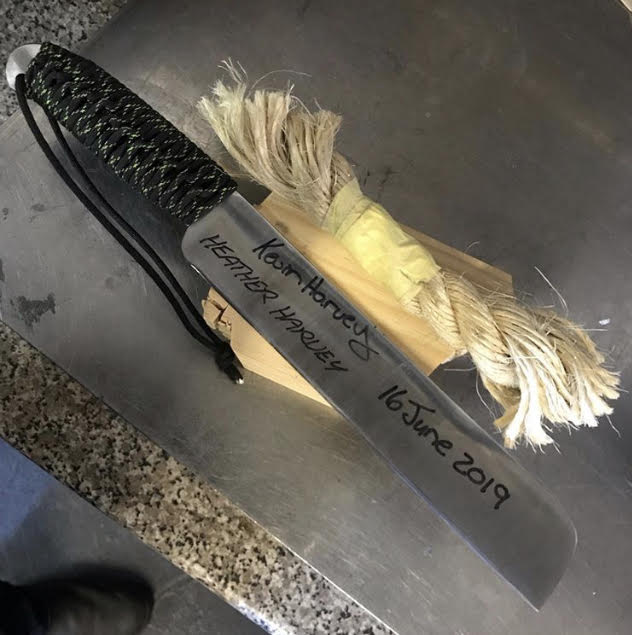

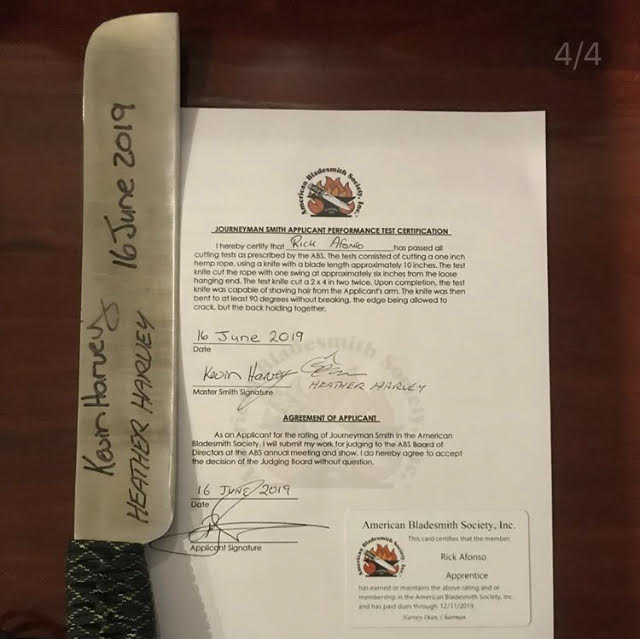

I was lucky enough to spend last week with my two ABS Mastersmith teachers (mentors) having some one on one time and critique / feedback on current work, with the end of the week set for the Cut and Bend Performance Test.

On Friday morning I passed the JS Performance test (This was my second pass, unfortunately my previous test result expires in April next year, a few months short of Blade).

As am now starting on my presentation knives for submission in June 2020 I spent quite a few hours discusssing the various parameters, things to focus on and what to avoid etc with Kevin and Heather Harvey (my Mastersmith teachers from ABS Intro to Bladesmithing Coiurse) and I borrowed an ABS Video from them on Judging JS and MS knives (the ABS video with Bert Gaston and Greg Neely).

I have now watched that DVD four times - it is a MUST WATCH if you want to find out some of the things the judges are specifically looking for, things to be careful of, things to stay away from (dont thing you will get anything over on the judges there are no new tricks - the Mastersmith judges have seen it all) - Re: Filework as mentioned above - if you put filework on your blade it will be carefully inspected and judged, very often with the viewpoint "what is he/she trying to hide with the filework? "

Do not submit DAMASCUS of ANY SORT (Blade / Fittings / Guard / Spacers / Ferrule etc) - DONT EVEN SUBMIT ANYTHING that LOOKS LIKE DAMASCUS (ie: no Wrought Iron)

Some of the suggestions are that you show variety in your submitted knives, try to ensure that you make no more than two of any particular type of knife, only use the best materials (preferably natural - ie: forged blades are traditional types of knives - try to stay away from Carbon Fiber, G10, Titanium etc. - use good steel, natural materials (Wood / Horn / Stag / Bone ...)

Good luck to the other prospective JS candidates for Blade 2020

Rick

Cape Town

South Africa

Rick

Congratulations.

Anthony

Congrats Rick!

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

Thanks Guys - appreciate it

First.... CONGRATULATIONS RICK!!!

As to the OP's post, I strongly agree with everything Kevin said. I too have failed my share of KSOs.

To piggyback on Kevin, one thing I've seen time and again, is a JS candidate who wants to "impress the judges", and in doing so, attempts/applies something to one of more of their presentation knives that is over their head, and done poorly. This usually results in a failure.

I think back to when I tested for my MS. I started almost 2 years out, and spoke with as many Mastersmiths as possible, asking for their input/opinions. The one constant was "Make it super simple, and super clean" What that means from my viewpoint is that ANYTHING applied as "embellishment" is just one more aspect that will be judged. That being said, IF you are supremely confident that your capability is there....go for it!

I also remember when the rule of NO DAMASCUS for JS testing came to be.....it was basically the same reason.... people were presenting damascus in their JS test knives that was HORRIBLE..... muddy, cold shuts, and any number of flaws/faults. Then when the individual(s) failed, the would whine..... "But it's damascus!" "I made damascus". In one instance I got fed up with an individual who followed me from the testing room, and into the show repeating that over and over. I finally turned to him and said..... "Yes! You made damascus....but it was crap damascus!" Not my proudest moment, but it got the message across.

When it comes to testing, don't try to impress, be yourself, build the knives you make, and build them to the Nth degree.

I also think ANYONE testing should do everything possible to have their knives reviewed, by as many MS as possible, giving yourself plenty of time to correct things those reviews revealed.

Ed Caffrey, ABS MS

"The Montana Bladesmith"

www.CaffreyKnives.net