Knife Design

Well hello everyone. This is our first topic of the month discussion. We felt that it will be a good way to get members involved in an active discussion on different topics concerning the art of knifemaking. Our first topic will be knife design.

By design I am thinking what makes the knife look right. Or when you are at a show, what elements about a knife make you or a customer want to pick that knife up and get a better look at it. Is it the blade shape? or the handle shape? The overall look? Etc. I will give a few thoughts on the matter and then we will see what you all have to say. For me the knife is not just a blade mated to the handle. The whole package must be taken into account. I keep hearing about flow and it is mentioned in the judging standards for JS and MS. All the parts of the knife must come together to form a pleasing look. I have been known to take a handle completely off a mostly finished knife because it just did not look right, something did not work to my eye. I prefer nice curves to sharp angles. How many sharp angles do you see in nature? For example if you make a four inch drop point hunter, do you want the handle coming straight back from the guard. Or, would a slight handle drop to go along with the dropped point look better. You would have a slight curve from the point to the back of the handle. I think this is more pleasing to the eye.

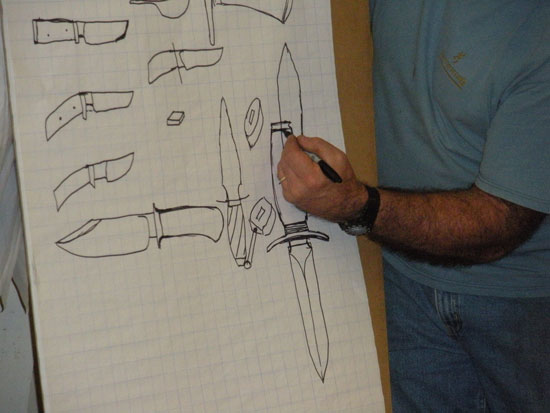

I am a great believer in drawing pads. Sketch out the idea you have for the knife with dimensions before you start on the knife. This gives you a good drawing to refer to. After you have the blade done, trace the outline on your pad, and then try sketching out different handles and guards for that blade and see what looks right. Ask for a second opinion, like your wife or husband. My wife is my best critic and my sounding board. Another option is look at books of custom knives and historical knives. This will give you lots of ideas. Go to the shows and hammer ins and look at the knives there. You can see so many different styles in one area, another great reference. What knives catch your eye and then think about why they catch your eye. What made you go WOW! that knife is really great.

Well this is just a start. So lets get some discussion going and see where it leads.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Brion, Sounds good to me but I found that once I taught my wife what to look for she never liked another one of my knives. ![]()

Kidding aside: Everyone has their own ideas and taste. My preference is as few straight lines as possible. Another point that I find pleasing is an "S" shape. If the overall knife has somewhat of an "s" or arc shape I find it most pleasing. Dropped handles seem to more practical as well as pleasing to the eye. There is the old "Form follows function" and it s justifiable in my opinion. I find it decadent to add the superfluous but then that is my opinion. One last thing that I think is frequently overlooked is the end of the handle. I have made many a "flat" ended handle until I noticed one of Jason Knights. The butt was "rounded; this looks great to me and I never looked back. Even more than a "rounded butt" I think the end of the handle should coincide with the curvature of the handle. It looks really awkward to me when the back or but is slanted forward or straight as opposed to "following the curvature of the handle. The a fore mentioned does not particularly apply to daggers but to most other knives.

Master Smith Jim Crowell lecture at Ohio Hammer-In contrasting good and poor knife design

Best regards,

Jim Crowell

Thank you for the response Jim. Isn't that the truth about having your wife look at your knives, Diane has the microscope eyes which usually results in me going back to the shop. I have also noticed and started the more rounded butt shape on the handles. Handles have always been an evolving design for me. I am still working on getting it right. I also find that a thinner guard is looking better. I used to have wide guards, but after seeing some knives by other smiths, I found that I like the look of a thinner guard, in width, looks really good in certain circumstances such as on a hunter or fighter. We never stop learning which is a good thing.

Take care

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Bear with me as I tinker with this subject. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

When it comes to knife design, I see it having two major parts. Thechnical and aesthetics. It might even be broken down into sub parts from there. Then the sub parts might show "leanings" or predominant elements that help define a maker's "style".

Usually a maker has one or the other as his strong suite and it's the rare maker that is known for both. One could list elements(1-5) of both aspects of good knife design and then start another chart about their present work to see if he can pinpoint a weakness to work on.

Technical -----------------------------Aesthetics

1______________________ 1______________________

2______________________ 2______________________

3______________________ 3______________________

4______________________ 4______________________

5______________________ 5______________________

I think a maker can chart his strong points on paper, if that's what it takes, then work on his weaknesses, and enable him or her to formualte a plan to realistically make improvement.

what about thickness ratio of fittings.

It always looks out of balance to me when the guard is 1/4" stock and the ferrule is 1/4" stock or smaller.

Usually if I'm going to do a ferrule with a plate style guard I will make the guard from .200 stock and the ferrule will be at least .25 but generally .375

what would you say the "appropriate" ratio between the two would be?

the "Golden Ratio" is 1.618034

so a .200 guard * 1.618034 = .323607

(I work almost exclusively in decimal, it saves my sanity)

Stephen,

I find it very interesting that you mention using the "Golden Ratio". Other names that I have seen for this principle are Golden Mean, Divine Proportion, Sacred Cut, and Phi. Bill Moran often talked about applying this principle when designing knives. I bought a book on the subject, but it seemed to me to be written by individuals with loftier artistic understanding than I, so much of it was difficult for me to comprehend. But, the mathematical calculations were included in the book and some applications were described, so I was able to learn a little from the book.

I've tried to apply the "Golden" principle to the designing of knives, but I have found it difficult to figure out how and were on a knife it can be used. I wish that I had paid more attention to Mr. Moran's lectures and had asked him to help me understand how he used the principle when designing a knife.

Your use of the formula to calculate guard to ferrule ratio seems quite logical. I am interested in hearing if you find the principle useful for any other aspects of knife design?

Does anyone else use the "Golden Mean" when designing your knives? If so, how and where in your knife design work do you apply it?

The problem I have with the Golden Mean is that it is more difficult to apply it with open ended curves. If my grinds were square and straight, it would be easier, but I dont like straight and square shapes and try to avoid it in my knives. Ron Smith's book "Advanced Drawing of Scrolls" covers the general principles and how they apply to .. well.... scrolls. Still, it has helped me to get a bettr understanding of it's application on 3 demensional objects, but I still have a ways to go.

I'd also like to clarify some of my ramblings from my above post.

The technical part of knife design is purely hard, clear cut aspects of fit, finish, geometry, etc apart from the aesthetics. Some knives are technically perfect in fit and finish, but might sit on the maker's table unsold, leaving him scratching his head as to just why. Aesthetics is the difference, or lack there of. We all know that curves, especially subtle curves are appealing to the human eye. They appeal to emotion. When a maker's work can evoke an emotional response from someone walking by his table, he is doing something right.

You cant put a number on possible elements used on knife design, whether technical or aesthetic. But I have to think in such terms to seperate the two parts and work on them.

I feel that I have a very long way to go, but there have been a lot of good comments in this thread that I feel I can add to.

A long time ago (another lifetime it seems) I was a student majoring in Commercial Art. We studied the Golden Mean in several drawing classes, mostly as it pertained to the human body and other forms of nature. I too, like Lin, am a bit lost as to how to best "intentionally" apply it to knife design. However, there was one trick that was offered to us that might be of help to those that choose to sketch their knives before they make them as Brion suggested. If there is something that is bothering you but you can't quite put your finger on it, look at your drawing upside down or in a mirror (or both upside down and in a mirror.) The idea is to trick your brain into using the left logical thinking hemisphere into evaluating what the right creative hemisphere has created. This trick is one that I use every time I draw a knife, and I have to say that the finished knives thatI drew first always seem to look and feel best. And, I can honestly say that when I have used this trick and studied the change(s), almost every time the problem was a proportional one.

Also, as mentioned above by Jim and Lin... Curves! I agree that as human beings we are drawn to curves, as everything around us in nature has curves and, like proportion, we naturally feel at ease with things that are proportioned properly and are more naturally curved and flowing.

Another aspect to consider is negative space and what I call white space... Negative and white space can be considered in many different ways, but for me as it pertains to knives, handles are a good example. Consider a Moran ST24. Would it's handle be as interesting without the silver wire inlay and minor carving that Bill applied to his handles? Would a brown, straight grained piece of oak be as appealing as a similarly colored and finished piece of curly maple? To some maybe, but the majority of folks will gravitate toward the fancier grained wood because the relatively large size of the handle (negative and white space) is being broken up by the grain structure of the curly maple. Another example would be a Scagel handle with it's sections of stacked leather, spacers and antler. In regards to blades,I personally feel that, a large blade such as an ST24 is as interesting as it is because of it's curves and the "white space" is broken up by plunge lines and the bevel of the clip. I also like the look of a big blade that has it's primary grind that ends a short distance from the spine. Again, it helps to break up the white space of the blade, creating something of interest for the eye. The tough part is keeping all of this practical as it relates to a blade's usefulness as a tool. It's easy to make things too busy and take away from simplistic beauty.

There is a good book for anyone inclined to study drawing, proportion, etc as it relates to the human psyche ... It's called "Drawing on the Right Side of the Brain". The book explains all of this in depth and at a level that is very easy to understand... And much better than I could ever hope to!

Now if I can only live up to what I've learned and make a decent looking knife one of these days. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Rick

I do use the golden mean sometimes, mainly with ricasso's. You can use it to determine the length of the ricasso. As Lin said this does not work so well when used with curves. Also, I have found that the golden mean formula does not work for every knife in regards to the ricasso. An example would be say a 9 1/2" bowie with a blade width of say 1 1/2". Pretty good sized knife, but the problem comes in when you have a certain piece of stag that you want to use and the golden mean calculation makes the ricasso to wide for the stag. So you have to adjust the ricasso to fit the stag and still have eye pleasing proportions. Then it is down to what looks right to my eye and does the knife still have the flow I am looking for. So back to the drawing pad and my original drawing and do some pencil experimenting. Lin also made a very good point about people having strengths and weaknesses. We all do and knowing what they are is a great help. Good stuff Lin. Rick excellent idea on the white or negative space. The Japanese have a principle they used and use today on swords, knives, art, etc. This is the principle of simplicity, less is more. This can be used in knifemaking. Instead of a real exaggerated curve make a slighter one to give a suggestion. I prefer a more subdued look, such as a damascus blade with ebony or blackwood, again simplicity. Too much activity either in the blade or handle can tend to make the knife look busy and distract the eye from the whole shape of the piece. Just some rambling from my sleep deprived brain. Good discussion guys.

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

While the Golden Mean may be difficult for us to apply in all areas of knife design, it is good for us to understand that these rules are evident in almost all of nature's structures. As the human eye has been familiarized to these often seen shapes, it is understandable that an object that conforms to the rules of nature's design is seen as "natural"; and therefore beautiful. If the shape of an object violates the rules of nature, we perceive the object as being "unnatural". A broom handle or a 2X4 board are not shaped according to natural design. Because these shapes are viewed as being unnatural, a knife with a handle that is shaped as round stick or a square block will also be seen as unnatural.

While following the rules of natural flowing lines is well and good, there is the issue of functionality of the piece for its intended purpose. In nearly all manmade items, there are exceptions to the rules of natural design to accommodate the functional aspects of the article. As on a car; the wheels must be round. On most knives, the edge must be a straight line. Too, the front of the guard is typically a straight line. To accommodate these hard lines into a visually pleasant design, it is important to understand that the human eye also accepts the concept of parallel lines. The architect Frank Lloyd Wright made himself famous for his use of parallelism in his architectural designs.

In parallelism, a single hard line is viewed by the eye as a place to stop, and becomes a focal point. Whereas, parallel lines convey the perception of movement and flow and will direct the eye to continue movement along the piece. On a car, the curved line of the wheel-well mimics the lines of the round tire and then redirects the eye to the horizontal lines of the bottom of the vehicle. On a knife, the spine of the blade and also the bottom of the riccasso mimic the straight line of the edge. The straight line of the front of the guard also needs a parallel line to compliment it, and so the use of a ferrule and/or spacers between the guard and handle material accomplish this. If the edges of the spacers are file-worked, this helps to gently re-direct the eye from the vertical line of the guard to the horizontal lines of the handle.

Learning how to incorporate the principles of natural design and parallelism into our knife designs is essential to creating an esthetically pleasing piece. Understanding how and why the human eye perceives lines to be acceptable is the beginning of this learning process. I'm sure that we all would benefit by studying other forms of art to learn how these principles of design are utilized. As knifemakers, we can learn from other makers by carefully examining a knife that we find particularly pleasing. Look for the makers use of natural design and parallelism to see how these principles were incorporated to create a knife that allows your eye to flow over the entire piece without being caught on an unnatural feature.

Good stuff guys!

I never really gave much thought to parallelism before. I'm glad that you brought it up Steve. It wasn't until today that I understood exactly what it was about a Searles Bowie that I like so much. For the most part, I don't exactly gravitate to blades that have parallel spine and edge, but the Searles Bowies always captivate me. Then it clicked. If you look at a good one such as the one Brian Thie has posted in the gallery, it incorporates both parallelism and the golden mean/ratio in the blade as well as the overall knife. If you break down the blade into two sections It follows the golden mean. First, there is a section of blade that the spine and edge are parallel. Then, as the belly of the blade begins to curve upward to the tip a second section is created. If you compare the length of the parallel section to the curved section, it appears to me that the dimensions fall very closely to the golden mean. Then, if the blade were a total of 8 inches and the handle is around 5, the knife as a whole follows the rule as well. Then, we have parallel's within the blade and the handle with a perpendicular Stop separating the two. Really makes me wonder about the background of Daniel Searles...

The ABS sells a video showing art knives and knives by known makers. It discusses the design elements of: line, parallelism, divergence and convergence, texture, contrast, and other design concepts in a slide presentation with narrative. I think it is a pretty good primer on these concepts. It explains and at the same time shows real knives and drawings to illustrate. The concepts are actually pulled from art design concepts and it also attempts to clarify the language we use. It can be difficult to have a dialogue and teach when different instructors are using different words to express the same thing or using the same work to express different concepts. I think it is pretty good, but then I made it and gave it the ABS. It was recorded at the anniversary hammer-in in Wyoming of the first ever ABS hammer-in a few years ago.

Dan

|quoted:

I prefer a more subdued look, such as a damascus blade with ebony or blackwood, again simplicity. Too much activity either in the blade or handle can tend to make the knife look busy and distract the eye from the whole shape of the piece. Just some rambling from my sleep deprived brain. Good discussion guys.

Brion

I agree that often more can detract from the overall appearance of the knife. I have often opted for a simple handle with a "busy" blade or vice-versa. This brings about a question however. If you are using a "busy" pattern in the blade, should you use pieces of the same damascus in the handle fittings to match the blade or go with more plain fittings (such as 416) so as not to detract from the blade? I realize that aesthetics is a very subjective subject but would like your thoughts.

Gary

Actually Gary, I tend to prefer damascus fittings for a damascus blade, now. They seem to tie the whole piece together. Just my opinion but a plain 416 guard with a darker damascus blade kind of gives an abrupt stop to the flow of the piece. Say you have a nice ladder pattern blade and opt for a darker handle material, so you have the two darker pieces, blade and handle, then this bright 416 guard, kind of an abrupt change, unless you maybe engrave the guard or do something like that. This is my thought on it, just my personal preference. I would like to hear what others have to say.

Brion

And then of course you have the antithesis to my statement with the dagger in my picture. But the guard and pommel were etched to almost a french gray. Just an evolving process.

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith