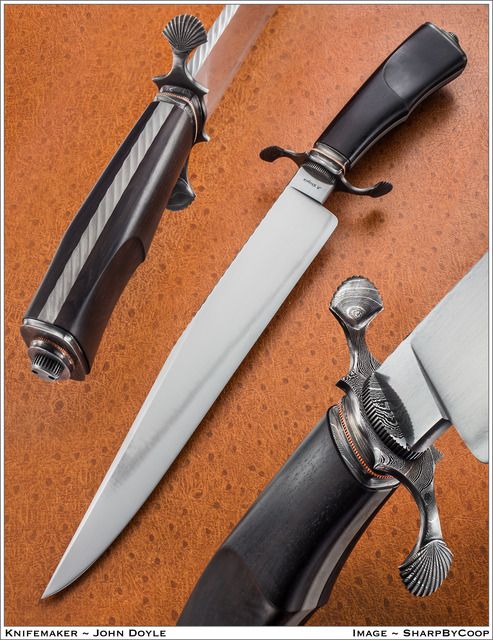

This piece was quite a while in the works and is for a great collector and friend of mine/ours here on this forum. This was a LOT of fun to make and enjoyed working on it. It was definitely the most complicated build I've ever undertaken. It is also the largest knife I've ever made.

Specs:

Hand-forged from W2 steel

13" of blade, 18 3/4" overall, .240" thick at the ricasso

Full distal taper, with an *almost* sharp clip (could easily be sharpened if desired)

Twisted steel filework on spine

Rounded ricasso edge

My own damascus fittings for the collars, shell guard, spacers, butt cap segments and finial

Coined copper accent spacers

Carved African blackwood handle

1084 steel frame, twisted steel on top to match spine side of blade and rounded and proud fit bottom frame to match the bottom of the ricasso

My friend and sheath maker extraordinaire, Claude Scott did a beautiful job making a sheath for this knife.

And thank you to Coop for the clear crisp photos that capture the true look of this knife SO perfectly.

Any comments and discussion welcome.

Very nice work John

Scott

Excellent John! Beautiful work. Just one question. When are you going for your JS?

Brion

Brion Tomberlin

Anvil Top Custom Knives

ABS Mastersmith

Quite a looker that one!

Is that a hint of hamon I see along the blade edge? The subtlety of it is very nicely applied. I especially admire the clam shell work on the guard. Too often I see this accent poorly executed and here it seems flawless. Do you use anything on the 1084 frame to resist tarnish and rust? It looks like there is a light application of cold bluing maybe?

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Thank you guys. I appreciate the comments.

|quoted:

Excellent John! Beautiful work. Just one question. When are you going for your JS?

Brion

Brion, I joined the ABS in April or early May of 2014 I think. Either way, the absolute earliest show I can test at is Blade 2017 which is when I will do it. Taking my performance test next summer. Thanks for the comments.

|quoted:

Quite a looker that one!

Is that a hint of hamon I see along the blade edge? The subtlety of it is very nicely applied. I especially admire the clam shell work on the guard. Too often I see this accent poorly executed and here it seems flawless. Do you use anything on the 1084 frame to resist tarnish and rust? It looks like there is a light application of cold bluing maybe?

Hi Joshua, yes this actually has a very nice and active hamon but it really is hard to except in person. It was achieved with no clay using time/temp control of my salts. It's a very interesting pattern but extremely difficult to capture in pics.

The frame is etched in FeCl and is not hardened so it matches the spine and ricasso edge of the blade, which are also not hardened. It came out looking pretty much exactly the color of the blade and is probably grayer in person than it looks in the photos.

I appreciate you guys posting your thoughts.

Beautiful knife John!! As Joshua mentioned, you did an excellent job of sculpting the shells. A maker's attention to details, is something that I appreciate.

This is the kind of work that speaks of planning and patience. The fit and shape of these parts did not just happen by accident did they John. Nice work.

Mind if I ask about the sheath? The coined plate in front of the guard; how does it work with the sheath? Or vise versa?

Thank you Steve and Lin.

|quoted:

This is the kind of work that speaks of planning and patience. The fit and shape of these parts did not just happen by accident did they John. Nice work.

Mind if I ask about the sheath? The coined plate in front of the guard; how does it work with the sheath? Or vise versa?

Hi Lin. No, this sure didn't happen without some serious drawing and planning and thinking. It took me longer to build by far than anything I've made yet. And I'm not a particularly fast knife maker anyway. <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//smile.gi f' class='bbc_emoticon' alt=':)' />

Claude built a little pocket so that the coined part in front of the shell guard nests inside the throat of the sheath. I'm not sure why he chose to do it that way but it works. I don't have any issues with it. I think the sheath could have been narrower if he had let it sit on top of the throat, like the shell guard does now. But either way, it's well made and very professional. There is an inlaid belt loop on the back of the sheath too that is very well done and neatly tucked out of the way.

Thanks for the comments and questions.

|quoted:

This piece was quite a while in the works and is for a great collector and friend of mine/ours here on this forum. This was a LOT of fun to make and enjoyed working on it. It was definitely the most complicated build I've ever undertaken. It is also the largest knife I've ever made.

Specs:

Hand-forged from W2 steel

13" of blade, 18 3/4" overall, .240" thick at the ricasso

Full distal taper, with an *almost* sharp clip (could easily be sharpened if desired)

Twisted steel filework on spine

Rounded ricasso edge

My own damascus fittings for the collars, shell guard, spacers, butt cap segments and finial

Coined copper accent spacers

Carved African blackwood handle

1084 steel frame, twisted steel on top to match spine side of blade and rounded and proud fit bottom frame to match the bottom of the ricasso

My friend and sheath maker extraordinaire, Claude Scott did a beautiful job making a sheath for this knife.

And thank you to Coop for the clear crisp photos that capture the true look of this knife SO perfectly.

Any comments and discussion welcome.

Amazing! You have allot of time and patience in this work of art. I can only hope to be at this level one day!

Thanks,

Jonathan S. Johnston