As I don't have much of a scrap pile I am starting out with a 2" wide by 1/4" of 1084 from the steel baron. Cut in half to 1" x 4". Guillotined the tang in at 1 1/2".First time posting pictures of anything I've done. As a hobbyist, this will take me longer then most. Slow and steady.

Instagram @drunken.bladesmith

X-Rhea design boning knife. I began with an odd ball piece of 52100 laser cut scrap that was 3/16 thick. Forged it down to 7" x 3/4" x 3/16. Goal was a 6-1/2" blade but fell short due to my lack of forging skill. After rough grinding I discovered where the missing steel was hiding. The last image is rough ground at 80 grit. I will post final product when complete.

Ya'll are ahead of me. I've had a few things come up. I'll be along soon. Good job guys!

Not sure when I'll get to finishing this up . I need to get back to commissions but I managed to get all the parts shaped and refined today, just a bit of polishing and etching left to do.

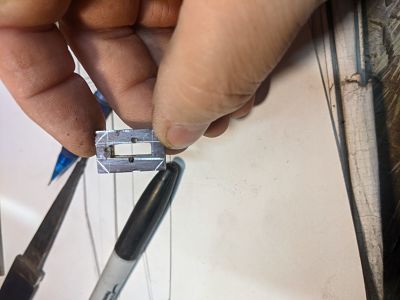

so I figured i would include this quick tip as well. when I am doing faceted handles I start with the spacers , I superglue the stack together then mark and cut the angles on the spacers. (with alignment pins)

from there I attach to the handle and trace the angles in with pencil on my surface plate. , then I sand down ot the lines on the grinder. I adjust from there with a file if needed. from then it just needs to be hand sanded out. for the spacer packet . I broke the stack apart , filed reliefs on the nickel silver and rounded the Nugold, it adds a little depth the the spacer without making a big thickness change in an all-ready slender handle.

from there I attach to the handle and trace the angles in with pencil on my surface plate. , then I sand down ot the lines on the grinder. I adjust from there with a file if needed. from then it just needs to be hand sanded out. for the spacer packet . I broke the stack apart , filed reliefs on the nickel silver and rounded the Nugold, it adds a little depth the the spacer without making a big thickness change in an all-ready slender handle.

Every one of these is looking good here! I did a very similar project in another thread in November 2019, and I am anxious to do another one.

I spent the last 3 days moving walls in a home remodel project, but I have tomorrow off and will try and get to the forge.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

As promised, I dug around and found several small pieces of scrap that would fit the bill including a Damascus cut off of unknown pattern. It measures 1/4" by 1" by almost 4" long.

I work from the blade back and do the tang last.

Once I have my blade shape to match my target,

I can cut that little piece of rebar handle off and start the tang.

Then I finish matching my template.

I got this one rough ground and hardened. I love when the pattern is visible out of the quench.

It's tempering now

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

Joshua, Looks great! I really like your WIP's for the detail you put into them. Thank you.

Instagram @drunken.bladesmith

Hi All,

Progress on this little knife is slow, as I'm squeezing it in alongside commission work, but I managed to get the blade rough ground and the handle block fit. I'm keeping it simple: just a blade and a handle.

Jordan

I got the handle and fittings all polished out. I still need to do a once over on the blade, add my mark and etch the blade.

This is a new handle material for me , it is local maple stump wood, I sent out to K&G and had stabilized as well as dyed black. It is interesting, works well for this one , but I am not sure I like it.. super chatoyant though.

MP

Everyone's contributions are great! keep them coming! looking forward to lots more!

That is a really nice shape on that handle Matt. I am digging that.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

I finished the blade out, etched it, marked it, got the guard and spacer stock fitted. Then I made a preliminary design drawing.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

I finished out the blade yesterday, re sanded out the flats to 1200 then etched my mark , finished sanding out to 1500 and etched in ferric and vinegar 3-4 cycles over about an half an hour cleaning with 2000 grit between cycles. then I stamped the acid out with baking soda and water and again with windex, then cleaned with WD-40. once dry I waxed the blade with johnson's paste wax and assembled the knife. It is a take down but with such and small thread (8/32) I may go back and glue it up.

Beautiful work Matt!

So I profiled and rough ground to 80 grit, clayed the blade back and heat treated and tempered. For the handle and guard I am going with mild steel, copper spacer and a piece of Elm I pruned from a tree in my backyard several years ago. Currently at a very worn 400 belt finish.

Instagram @drunken.bladesmith

I did a little work on the handle yesterday and got the pieces roughed out and fit to the tang.

After getting all the blind pins set I can keep it all together for shaping with some threaded rod.

A little shaping and then hand sanding in a Panavise.

Still needs some work, but it's getting there.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€