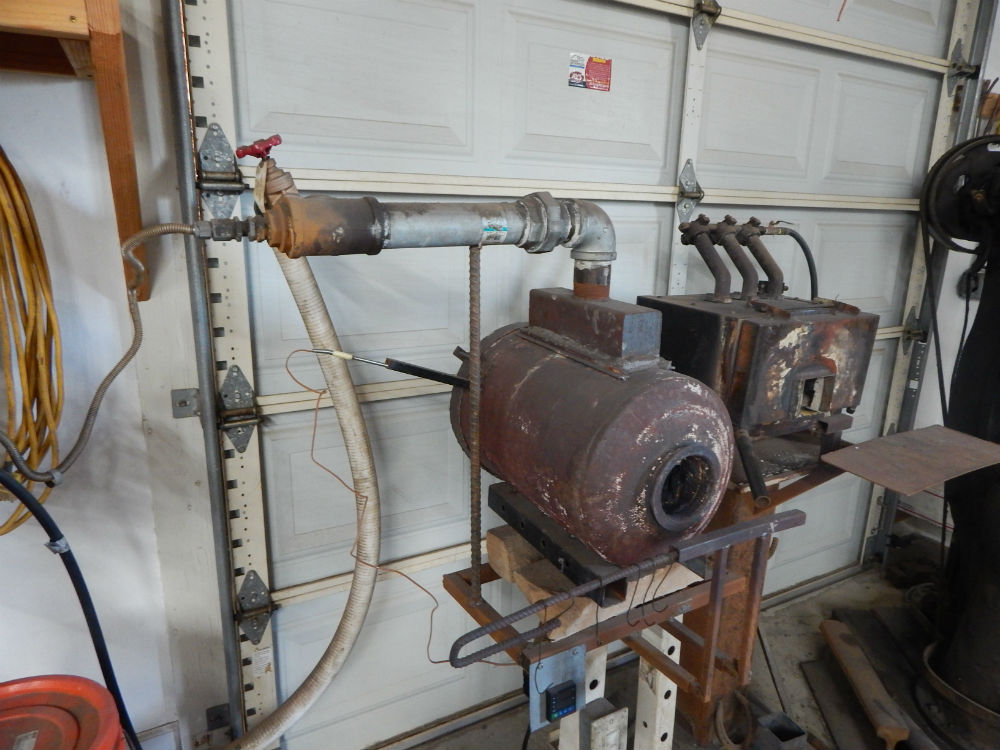

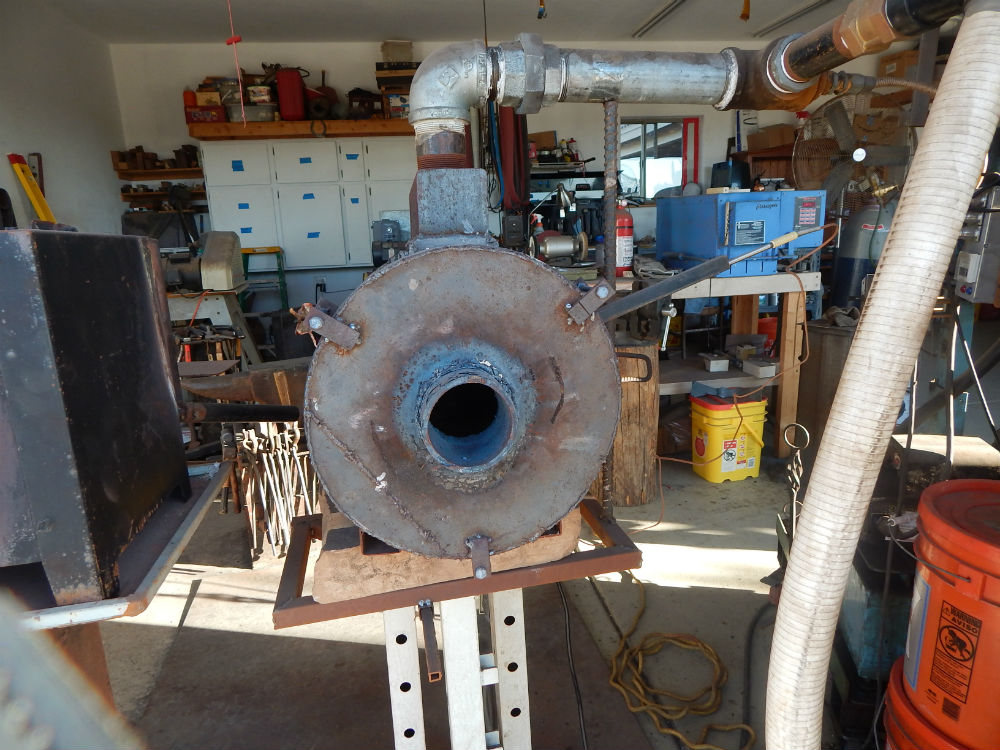

so I am finally building myself a ribbon burner. I want to avoid to much heat in a smaller area and over cooking potential...........so this shell is 28" l x 10" w x 10"total with 6" high opening. The ribbon burner is 20" with 19" of fuel / flame orifices. Where is best to place the parameter needles to accurately / best register the internal temps in your experience ?? Also working out decisions on how I want to complete the fuel rail and blower mount........any experienced advise would be epic......

Minimum Effort = Minimum Results every time

WOW, That is the biggest ribbon burner I have every seen. I wish I could help you out but I made just a regular blown burner to keep it simple for myself. But I have seen a lot of ribbon burners and are you sure you need 1 that big?

Want to see more of my work follow me on Instagram:JasonVolkertKnives

Want to get in touch with me [email="[email protected]"]Email[/email] me.

honestly my mind was in a place where I just wanted to do this once........so franken forge is coming to life.

Minimum Effort = Minimum Results every time

I personally do not like this shape, I think this shape is not good for REDOX atmosphere control, I prefer the vertical forge furnace <img src=' http://www.americanbladesmith.com/ipboard/public/style_emoticons//rolleyes.gi f' class='bbc_emoticon' alt=':rolleyes:' />

I do not understand this question: "Where is best to place the parameter needles to accurately / best register the internal temps in your experience ??"

What are "parameter needles"? Do you mean thermocoupler/temp probes? If so, usually those are placed through the top, off to one side at the rear, but that's on a much smaller round forge. Your forge design is very different from the typical in terms of shape and size, and your front door is quite large when compared to most ribbon burner forges.

You may have to set more than one temp probe and you may not get an accurate reading doing that. The burner is quite long and with only a center feeder, you are not likely going to get even burn/heat along the entire length. That, coupled with the drastically differently sized doors will likely cause most of the heat to escape out the front. Looking at your setup, I anticipate a hot zone in the center and rear of the chamber.

The blower can be mounted almost anywhere. Mine sits on the floor and is attached to the burner assembly with a piece of heavy rubber hose attached to a gate valve. The gas line can also be attached using a long and flexible gas appliance connector and does not have to be in close proximity either.

Here is my ribbon burner forge. It is a 12 inch diameter tank, 17 inches long and the front door is 3 inch diameter hole. That gives me a working chamber about 16 inches long, plenty for forge welding billets. You can see the thermocouple location, and my ribbon burner is mounted straight down in the top center. The ribbon is only 12 inches long and has a similar set of burner holes as yours does: 3 rows of 1/4" holes over a 10 inch length.

The white hose in the back leads to the blower.

I also made the rear of the forge removeable for easier cleaning or relining when the time comes.

Joshua States

www.dosgatosforge.com

https://www.youtube.com/channel/UCdJMFMqnbLYqv965xd64vYg

https://www.facebook.com/dos.gatos.71

Also on Instagram and Facebook as J.States Bladesmith

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.â€

|quoted:

I do not understand this question: "Where is best to place the parameter needles to accurately / best register the internal temps in your experience ??"

What are "parameter needles"? Do you mean thermocoupler/temp probes? If so, usually those are placed through the top, off to one side at the rear, but that's on a much smaller round forge. Your forge design is very different from the typical in terms of shape and size, and your front door is quite large when compared to most ribbon burner forges.

You may have to set more than one temp probe and you may not get an accurate reading doing that. The burner is quite long and with only a center feeder, you are not likely going to get even burn/heat along the entire length. That, coupled with the drastically differently sized doors will likely cause most of the heat to escape out the front. Looking at your setup, I anticipate a hot zone in the center and rear of the chamber.

The blower can be mounted almost anywhere. Mine sits on the floor and is attached to the burner assembly with a piece of heavy rubber hose attached to a gate valve. The gas line can also be attached using a long and flexible gas appliance connector and does not have to be in close proximity either.

Here is my ribbon burner forge. It is a 12 inch diameter tank, 17 inches long and the front door is 3 inch diameter hole. That gives me a working chamber about 16 inches long, plenty for forge welding billets. You can see the thermocouple location, and my ribbon burner is mounted straight down in the top center. The ribbon is only 12 inches long and has a similar set of burner holes as yours does: 3 rows of 1/4" holes over a 10 inch length.

The white hose in the back leads to the blower.

I also made the rear of the forge removeable for easier cleaning or relining when the time comes.

thank you this is my first ribbon burner and hard to get any advice. there is a defuser plate on the inside of the burner that runs the length I am hoping with balance out the flow but if not reworking will be required. Yes I meant the probes, I have 2 of them and was planning on splitting length in 1/3's and mounting at the 2 split lines but was unsure at what position in relation to burner I should have been clearer apologies for that. Thank you for the advice I appreciate it 🙂

Minimum Effort = Minimum Results every time

You need to keep any thermocouple probes away from direct contact with the flame from your burner.

I agree with Joshua that you will have a great deal of trouble balancing the flow for such a long assembly. Also questionable whether such a long forge will be efficient and effective for forging (though likely pretty good for heat treatment). Make sure you seal that muffler pipe to the burner mixer. Last thing you need is for a pressurized air/gas mixture to be exiting at the joint.

All of the ribbon burners I have built anything over 10" has cracked. But curing the refractory as per the instructions is crucial.

|quoted:

You need to keep any thermocouple probes away from direct contact with the flame from your burner.

I agree with Joshua that you will have a great deal of trouble balancing the flow for such a long assembly. Also questionable whether such a long forge will be efficient and effective for forging (though likely pretty good for heat treatment). Make sure you seal that muffler pipe to the burner mixer. Last thing you need is for a pressurized air/gas mixture to be exiting at the joint.

not been on in a bit, went away from the muffler tubing entirely and all 2" black pipe. It is near done so I will see if the dice roll works out in my favor :-). The refectory for the casting is current engineered high temp refectory not cutting any corners here. Why the process has been slow.......was actually turning down bushing to tack into body today for parameter needles. I figure if the air / fuel is not spread enough I will cut off top pipe and build a conical with a another diverter inside to force the spread.

Minimum Effort = Minimum Results every time

thx again for the input fella's it helped, it is near done so I will see soon if all of this was a useful venture 🙂

Minimum Effort = Minimum Results every time

That's slick. I like the door design. I always wire up a NC solenoid on the gas line in case I lose power it will shut the gas off. I wire up my fan on a light switch. It turns the fan on and opens the solenoid. It is just an added layer of safety.

So those of you who use the ribbon burners does anyone have a design that works well? Also what diameter is your forge and how long is it? I am thinking of building a ribbon forge and any suggestions would be great.

Thanks

sorry not been on in a while folks, struggling with health and life. That said I finished my frankenforge build. I am honestly really happy with it, not real skilled at posting video's here and kinda gun shy about breaking rules. So here is the link to my FB page where I just posted it running, should be able to use it some and start getting used to the new tool today 🙂

https://www.facebook.com/ginger.breadman.10690203/videos/269090224056781/

Minimum Effort = Minimum Results every time

Looks great. Nice job.

|quoted:

Looks great. Nice job.

thank you, be happy to get into thing once propane supply opens Monday.....lol

Minimum Effort = Minimum Results every time