Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke

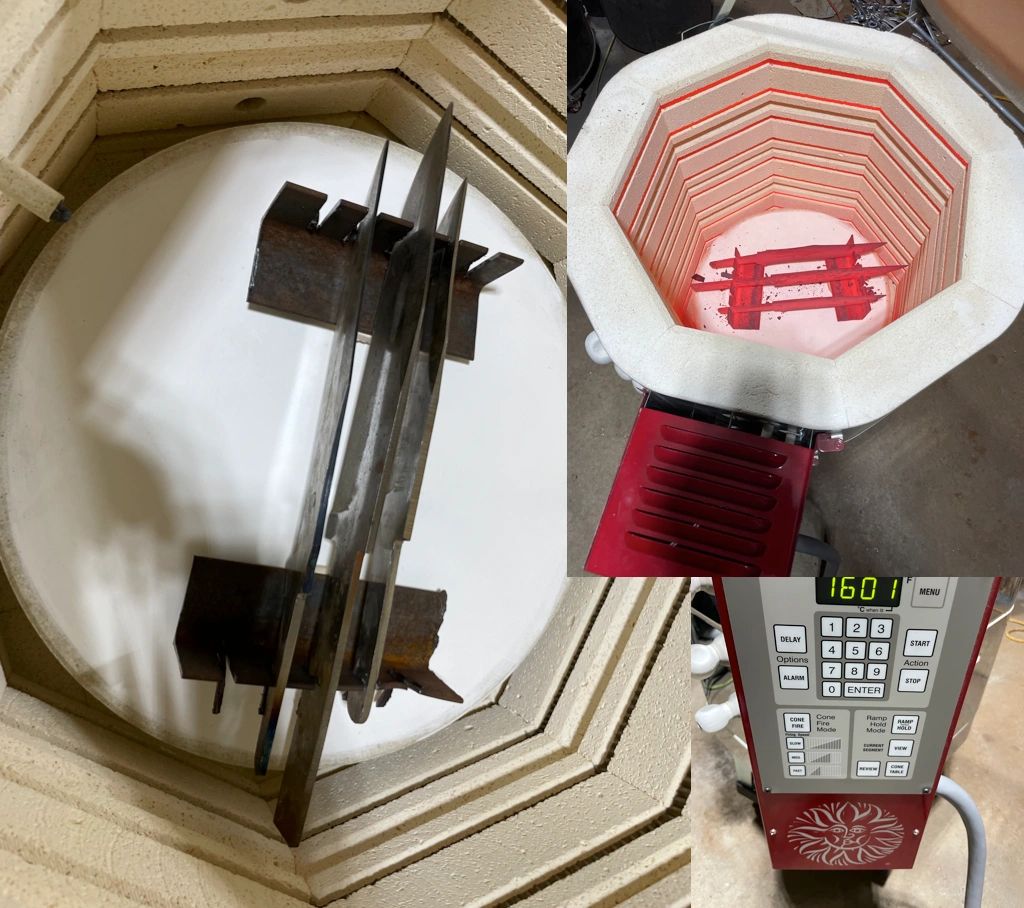

Hello Wendell. Jen Ken makes vertical heat treating kilns that are pretty nice. Have one that is 31" interior depth. Works like a champ. I know a number of people that us vertical kilns for swords. Makes sense to me as it gives you less chance for warps. I say go for it.

Brion

i have the shorter version of the Jen Ken, but can vouch for it. The jen ken Excalibur, which is the one Brion mentions as i recall can be broken down to a shorter height as well when you don't need to run it for large blades.

I built a vertical HT furnace from an old 100 pound propane tank. It is simply lined with ceramic blanket and has a 1" venturi style propane burner for heating. It has two temp probes (K-type thermocouplers) set at 1/3 points on the height. There is a vent pipe at the bottom of the forge/furnace to help draw the heat downward. This is critical to achieve even temperature through the forge body.

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.”

The burner enters low on the forge. With minor adjustments to the gas/air mix, I can either hold it around 1480* F for quenching, or 750* F for tempering.

“So I'm lightin' out for the territory, ahead of the scared and the weak and the mean spirited, because Aunt Sally is fixin’ to adopt me and civilize me, and I can't stand it. I've been there before.”

Thanks everyone, I hadnt seen the jen ken stuff, it just seemed to make sense when I was thinking about it. Im trying work out a way for the kiln to sit vertical OR horizontal. Ive purchase all of the bricks, PID, kanthal etc. just waiting on a few more parts I had to get from Aliexpress (shipping there takes forever). I will try and document what I did along the way. In a past life, I used to be an electrician before I learned they work hard, so not very scared of the wiring. I am a bit reluctant to post wiring diagrams due to legal issues if something happens. I may just say refer to the wiring diagram that comes with the PID.

Bob Bryenton

Solar Storm Group Ltd.

Phone: (780) 953-0016

Email: [email protected]

https://www.solarstorm.ca

“The only way of finding the limits of the possible is by going beyond them into the impossible" -- Arthur C. Clarke